Design and Engineering.

Thomson Fasteners is your partner for fastener design and engineering expertise. Our key engineering and production teams have years of industry experience building cost effective fastener solutions.

Many of our custom parts and engineering successes are the result of working closely with our customers to target areas for redesign such as:

- eliminating assembly bottle necks

- increasing part consolidation

- combining multi piece components into one

- converting parts away from high cost processes

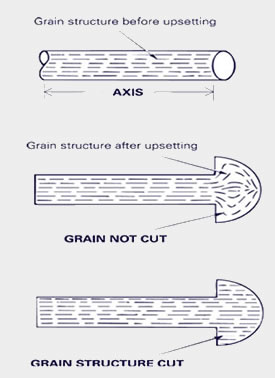

Our processes are advantageous over higher cost methods such as hot forging, casting, powdered metal, machined parts/screw machining, weldments or reinforced plastics/composites.

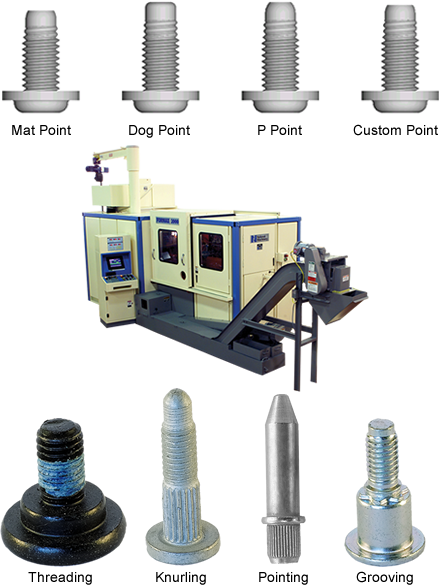

Thomson Fasteners produces fasteners for all automotive/industrial applications, complete with finishing, heat treatment and thread-seal/adhesives to customer specifications. Typical use cases include double-ended studs, hinge-pins, T-head bolts, self-tapping and standard threads.